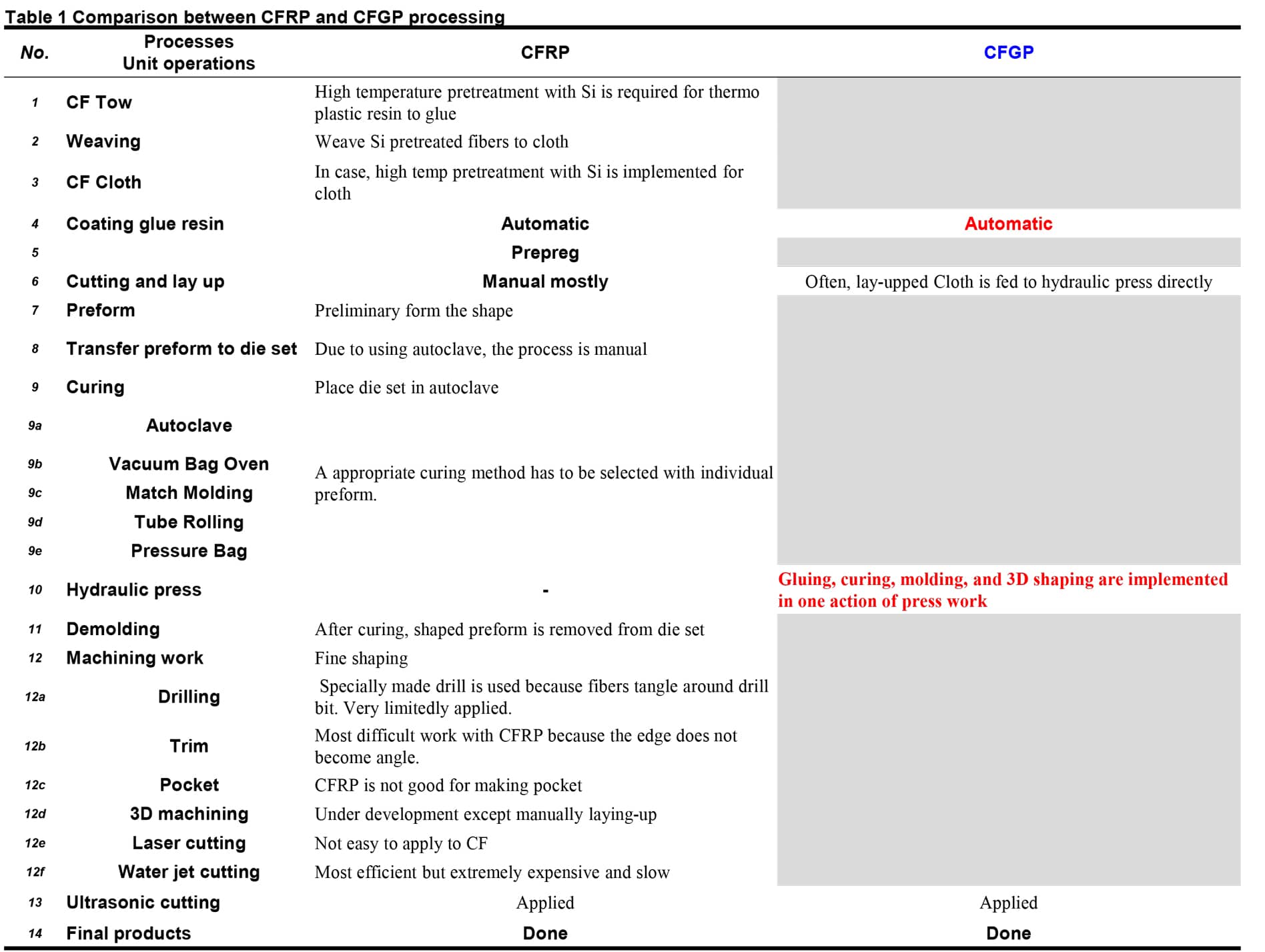

Carbon Fiber Glued Press or CFGP® is manufactured with newly developed glue-resin by a simple mechanical press. It provides sharp edging-shaping and 10 mm depth dent, and shining and smooth surface without polishing by merely press. The adhesive strength was tested, and exhibited high durability that meets to auto-engine parts in oil. Since CFGP® does not include epoxy at all, it does not have brittleness, and shows bending-resiliency.

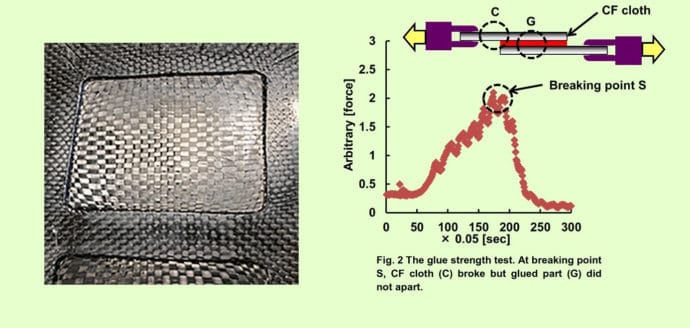

CFGP semi-commercial sample for A4 size. 8 layers of CF cloth was glued and pressed. Gray wave-like patterns on the surface are position markers during the press. The sample is available for a customer’s evaluation from Siddarmark.

CFGP® Offers:

- Low cost CF products fabricated by machine press

- Metal press mold is applicable

- Ultra light weight (ρ = 1.2)

- No impact brittleness even by bullet shooting

- Choice of hard and soft types

- Durability: Thermally ~ 200 °C & bullet proof

- Thinner than CFRP: 2 mm for layered 8 sheets of CF cloth

![]()

All inquiry should be made to Siddarmark, LLC.

Please contact us.

Overcoming disadvantages

Carbon Fiber Glued Press® (CFGP®) was developed for the broader use of CF clothes. As of today, CF and CF clothes are processed with thermo-set and/or thermo plastics to be various CF prepleg and CFRP. Both of those products with epoxy resins have been manufactured and applied to fishing rods, rackets, golf shafts, aircraft bodies, autoes, and so on. Some manufacturers address use of thermo plastics that are more or less the similar to epoxy.

The prepleg and CFRP are required to shape by carving and cutting (often drilling) with the expensive specific machines and labors. Unfortunately a large amount of the CF in prepleg is drilled and becomes the shredded waste. Also, the epoxy-prepleg and CFRP are brittle causing sudden rupture. CF prepleg with thermoplastics is under development; however, it need pretreatment of CF surface to glue, which is costly and time-wasting. Those manufacturing limits prevent CF applications from the universal and broader use.

CFGP® allows to shape 3D sharp edges without extra cost

CFGP® is fabricated from CF cloth, in which CF cloth is simultaneously glued and shaped by a conventional press machine with 100% thermoplastic resin, resulting the shorter processing time and reducing the manufacturing cost dramatically.

Even the plate with 8 layers of CF cloth gives the sharp edges. The specific density is at 1.2 with the thickness of 1.6 through 2 mm (adjustable). The surface can be painted with non-solvent type paint as shown below. It is durable for a long period of years against UV, sudden temperature change, high temperature, and oil.

Most of CFRP/CFRTP can be replaced to CFGP®. Furthermore, steel plate can be replaced to CFGP®.

Video: With this shooting the durability of the CFGP is tested. The CFGP consists of layered CF cloth backed by Vectran (Polyamid cloth). The shooting tested the glue performance. If the glue was not strong enough, the CF cloth would fall apart. If the glue was strong enough, the layered CF cloth would just receive a bullet hole.

The shooting test result shows, the strength of the glue. The CFGP can be used for light weight bullet-proof materials. CFRP is brittle and cannot have such durability. Many CFRP/CFRTP users have their problems because CFRP gets cracks even by small stone hitting. Suppose a stone flies to your car front shield and makes a crack on the surface. This is the reason CFRP is not applied to auto bodies.

It is flexible and soft CFGP without loosing mechanical strength. The soft CFGP is made with several-ply of CF cloth.

[embedyt] https://www.youtube.com/watch?v=hrophl97cFk[/embedyt]

Double layers of CF cloth give more than double in physical performance

A pre-treatment of CF surface is not required, CFGP® is extremely durable physically and chemically in addition to low cost processing. Furthermore, the glued part is strong enough, the performance depends on CF cloth used. Furthermore, our technology brings synergetic performance. For example, double layers of CF cloth give more than double in physical performance by changing knitted directions. Most of applications such as auto bodies, drone parts, and the others need only 2 to 3 layers of CF clothes of CFGP® .

![]() Siddarmark, LLC offers two types of CFGP®: High temperature resists (> 200 deg C) and standard (60 deg C.). The former is good for the ultra harsh environmental condition and long life.

Siddarmark, LLC offers two types of CFGP®: High temperature resists (> 200 deg C) and standard (60 deg C.). The former is good for the ultra harsh environmental condition and long life.