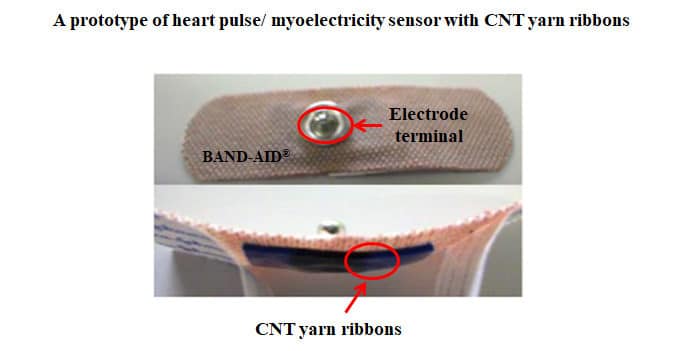

We have already begun to apply CNT yarn to automation parts, robots, human interface for virtual reality, cyborg with active research and development and more.

Professor, Yasuhiko Hayashi’s Laboratory of Okayama University Graduate School of Natural Sciences Laboratory and Sugita Electric Wire Co., Ltd. (President Sugita, Saitama Prefecture) collaboratively developed CNT yarn spinning technology using high purity vertically-aligned double-walled carbon nanotube (DWCNT).

This CNT yarn is manufactured under quality control on diameter, conductivity, twist angle, and mechanical performance. Although the CNT yarn is not subjected to chemical or physical treatment, it has characteristics such as low electrical resistance at the same level as metal, specific strength exceeding carbon fiber, and has high-speed motion response sensing properties.

![]() The first commercial CNT sensor as ribbon is available.

The first commercial CNT sensor as ribbon is available.

Please contact us

CNT yarn spinner

The technology developed newly uses a proprietary manufacturing method called dry vertically-aligned growth CNT array, where the catalyst remains on the substrate. As a result, this CNT yarn has metal impurity content lower than the measurement limit.

CNT yarn spinning

On the other hand, as the catalyst remains in the CNT in a typical wet or dry production method, it is necessary to remove impurities in a later process.

By using the DWCNT array of the same length and diameter, the CNT yarn is flexible and smooth in addition to being homogeneous due to the no-requirement for chemical and physical post-treatment. The beneficial characteristics may avoid abnormal current generated between metal and carbon.

Response speed adjustable

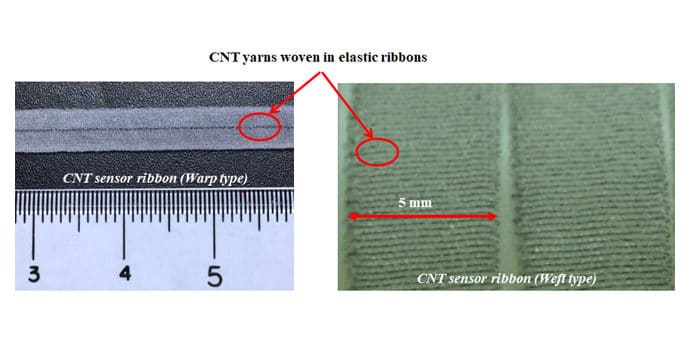

The CNT yarn is manufactured and can be obtained as a woven-fabric ribbon that is easily applied industrially. When used as a motion sensor, the response speed of the CNT yarn theoretically is approximately 0.1 millisecond, and as the ribbon it is 1 through 10 milliseconds depending on the applications. Response speed is adjustable by woven patterns of the ribbons. With the CNT yarn ribbon sensor, robots that do not grasp the object firmly by the numerical control methods will be dramatically improved. The new CNT yarn ribbon will be a product that realizes high production efficiency and AI introduction. Furthermore, as a human interface for progressive virtual reality, we can project human motion to every corner in the world of VR.

CNT yarn flat surface speaker

The company also develops and plans to apply this CNT yarn production to small and lightweight fiber artificial muscle, metal plated CNT cable, ultra-thin speaker with thickness less than 10 microns. Especially, as the need for weight reduction of automotive wire harnesses is increasing, gold and copper plated CNT yarns are scheduled to be industrialized in the middle of 2018.

SugiKuro® High-Speed Strain Sensors

SugiKuro® High-Speed Strain Sensors are manufactured from VA DWCNT, using the technology developed by Prof. Y. Hayashi at Okayama University in Japan. The patents are applied. Several institutes developed and reported high-speed strain sensors using aligned CNTs. However, none of commercial manufacturers had offered such a high quality product in ribbon and/or yarns until SugiKuro® High-Speed Strain Sensors were introduced. Now, users including small start-up venture companies enjoy developing the new applications without the inconvenience or annoyance of the preparation of the CNT ribbons or yarns.

SugiKuro® High-Speed Strain Sensors are made with 100% dry process and impurity is almost zero, because a new technology was developed. The easy-peel-off DWCNTs leave catalyst metal on the substrate. The number of layers of CNTs is around two. These superb characteristics brings the consistent performance.

SugiKuro® High-Speed Strain Sensors can be applied to chemical sensors such as hazardous chemicals, food spoil, and odor of cancers. Chemical modification is not provided by Siddarmark, LLC.

SugiKuro® High-Speed Strain Sensors are supplied as wound into a bobbin. A flexible and stretchable substrate is not attached; the users can choose their preferred substrate. This allows the users to develop their own original sensors. To avoid any biological troubles, it is recommended to prepare appropriate facility and equipment recommended by National Institute of Occupational Health and Safety in the United State of America*.

![]() Siddarmark, LLC provides SugiKuro® High-Speed Strain Sensors at reasonable price; the price can be negotiated.

Siddarmark, LLC provides SugiKuro® High-Speed Strain Sensors at reasonable price; the price can be negotiated.

Please contact us.

* NIOSH, “Building a safety program to protect the nanotechnology workforce: A guide for small to medium-sized enterprises (NIOSH Pub. 2016-102).