Siddarmark, LLC successfully commercialized a new technology to fabricate carbon fiber cloth, which replaces the current CFRP / CFRTP.

Siddarmark, LLC established a corporate group five years ago to overcome the processing difficulty and to eliminate fragility weakness of CFRP. We, as a result, launched Carbon Fiber Glued Press® or CFGP®. Carbon fiber exhibits excellent physical and chemical properties; however, the current processing method with epoxy resin brings brittleness intrinsically. Even though some advocate making CFRTP with thermoplastic only, it includes a small amount of epoxy that causes stress cracks. Siddarmark found a miracle way to glue CF cloth with 100% thermoplastic resin.

Siddarmark, LLC established a corporate group five years ago to overcome the processing difficulty and to eliminate fragility weakness of CFRP. We, as a result, launched Carbon Fiber Glued Press® or CFGP®. Carbon fiber exhibits excellent physical and chemical properties; however, the current processing method with epoxy resin brings brittleness intrinsically. Even though some advocate making CFRTP with thermoplastic only, it includes a small amount of epoxy that causes stress cracks. Siddarmark found a miracle way to glue CF cloth with 100% thermoplastic resin.

CFGP® Basic Characteristics

- A simple mechanical press machine is applicable. The depth drawing is up

to 2 mm in case of eight sheets of Mitsubishi TR 3110 M, Toray CO 6142

etc. (the same below). - Ultra light weight (density = 1.2)

- No Brittleness: There is no brittleness even by bullet shooting.

- Impact test: No cracks, or dent less than 1/10 to STCC 1.6 t.

- Flexibility: Selection of hard type and soft type

- Durability: Two types of guaranteed temperature – 20 to 60 ° C and – 20 to

200 ° C (Ask us the higher temperature resistance, if necessary). Oil

resistance was tested in the engine oil in accordance with an automobile

manufacturer standards. - Thin finish: 1.6 to 2 mm thick (adjustable) for 8 sheets layered.

CFGP® Fabrication

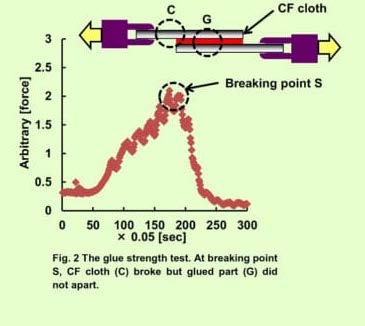

CFGP® was developed to use CF cloth widely and inexpensively. Although CFRP process often requires pretreatment of the CF cloth or making the prepreg before molding, CFGP® can be shaped without them. Furthermore, it does not need to use an expensive machine or tool to shape. Therefore, the yield of CF is very high and only press edging becomes a loss. Press can be conducted at a normal temperature and atmosphere. Cycle time is no longer than 20 minutes. The hardness is adjustable. From the bullet shooting test and scientific analysis, the adhesion strength after the press molding process is high (in the right figure). Since the adhesive resin consists of hydrocarbon, there is no trouble like GFRP at recycling or disposal. The metal mold for ordinary metal work needs very slight modification. Siddarmark advises you your mold remolding.

CFGP® was developed to use CF cloth widely and inexpensively. Although CFRP process often requires pretreatment of the CF cloth or making the prepreg before molding, CFGP® can be shaped without them. Furthermore, it does not need to use an expensive machine or tool to shape. Therefore, the yield of CF is very high and only press edging becomes a loss. Press can be conducted at a normal temperature and atmosphere. Cycle time is no longer than 20 minutes. The hardness is adjustable. From the bullet shooting test and scientific analysis, the adhesion strength after the press molding process is high (in the right figure). Since the adhesive resin consists of hydrocarbon, there is no trouble like GFRP at recycling or disposal. The metal mold for ordinary metal work needs very slight modification. Siddarmark advises you your mold remolding.

CFGP® Making Yours

As the surface of CFGP® is smoother than CFRP, the polymer film is laminated at the press work (in the right). In addition, the lower side picture shows an example of the weaving pattern of the new CF cloth made by Kyoto Nishijin ©, the most famous traditional Japanese KIMONO weaving. Not only “carbon patterns” but also the artistic CF cloth is applied.

As the surface of CFGP® is smoother than CFRP, the polymer film is laminated at the press work (in the right). In addition, the lower side picture shows an example of the weaving pattern of the new CF cloth made by Kyoto Nishijin ©, the most famous traditional Japanese KIMONO weaving. Not only “carbon patterns” but also the artistic CF cloth is applied.

In addition, it is also possible to sandwich polymer fiber cloth (eg. Kuraray Vectran®) or nanofiber cotton for processing, which strengthens bullet and pebble-collision proof performance.

More information on CFGP® can be found here at Siddarmark.com.